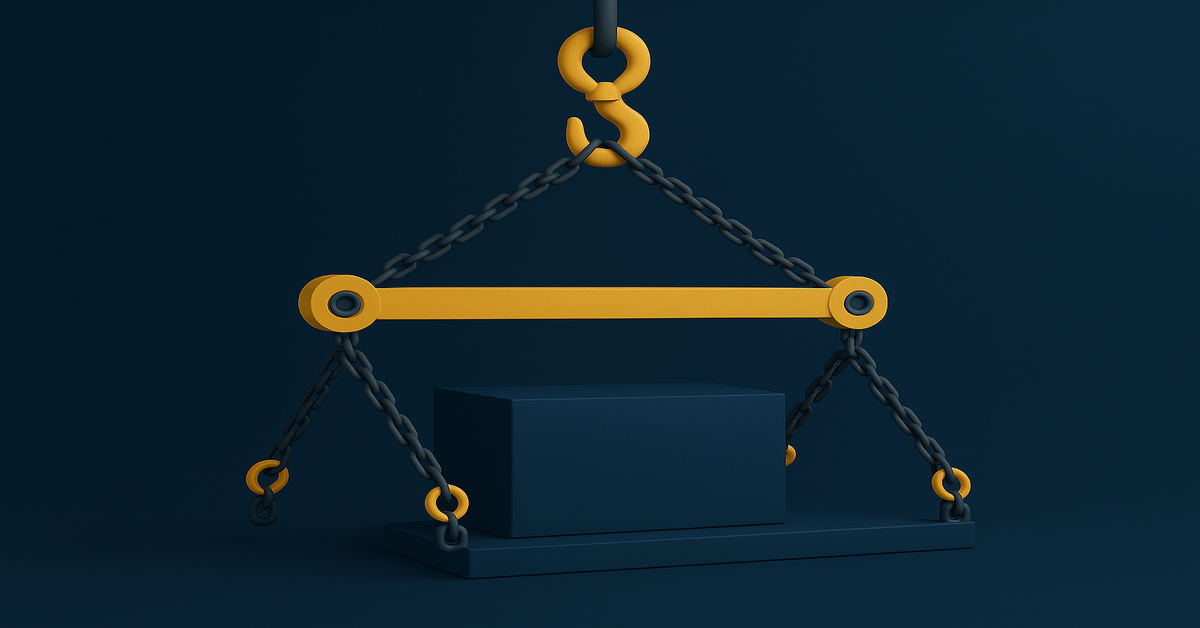

The term spreader bar may sound simple, but its importance spans across industries, construction sites, transport operations, sailing, and even specialized equipment handling. It is one of those engineering tools whose value lies not in complexity but in practicality, as it makes lifting, spacing, or balancing tasks safer and more efficient. Understanding what a spreader bar is, how it works, where it is applied, and why it matters requires looking at its design, its physics, and the wide range of sectors that use it.

In this comprehensive article, we will explore the concept of the spreader bar in detail. We will begin with its basic definition, examine its design principles, identify its key types, discuss its role in different industries, and evaluate the benefits and challenges associated with its use. We will also provide structured tables that show comparisons, applications, and safety aspects. This guide is designed to be accessible, detailed, and useful for both beginners seeking to understand spreader bars and professionals wanting an organized resource.

What is a Spreader Bar?

A spreader-bar is a device used to distribute load in a controlled and balanced way. Its design is typically a horizontal beam or frame, fitted with lifting points on each end, that connects to a crane, hoist, or lifting system. By attaching slings or chains to its ends, the spreader bar ensures that the load beneath it is lifted evenly, preventing bending, tilting, or damage.

The concept of a spreader-bar relies on the principle of spreading the load over a larger surface area, hence the name. Instead of concentrating the stress on a single lifting point, the bar extends the load across multiple points, which increases stability and safety. This design also makes it possible to lift awkward or fragile objects without distortion, such as large containers, machinery, pipes, boats, or structural frames.

Core Design Principles of a Spreader Bar

The engineering behind a spreader-bar is straightforward but precise. It includes:

- Horizontal Beam Structure: The bar is typically a steel, aluminum, or composite beam that provides structural rigidity.

- Lifting Lugs/Eyes: These are the attachment points for the slings, chains, or ropes that connect the load.

- Top Connection Point: This is the central lifting eye where the crane hook connects.

- Load Distribution: The geometry ensures forces are transferred vertically into the bar and evenly distributed to the load.

- Safety Margins: Bars are rated for specific load capacities, with safety factors built into their design.

Types of Spreader Bars

Spreader-bars come in many variations, depending on the task, industry, and load type. Below are the most common types:

| Type | Description | Typical Application |

|---|---|---|

| Fixed Spreader Bar | Standard rigid bar with fixed length. | Lifting containers, beams, and machinery. |

| Adjustable Spreader Bar | Length can be adjusted for different load sizes. | Construction sites, diverse load handling. |

| Telescopic Spreader Bar | Extends or retracts like a telescope. | Shipping containers, irregular loads. |

| Modular Spreader Bar | Built with sections that can be bolted together. | Heavy lifting, offshore operations. |

| Lightweight Spreader Bar | Aluminum/composite, easier to transport. | Sailing rigs, smaller lifting needs. |

| Specialized Spreader Bar | Custom-designed for unique loads. | Aerospace, delicate equipment. |

This variety ensures that spreader-bars can be adapted for multiple industries, from construction and logistics to marine operations.

Applications of Spreader Bars

The use of spreader-bars spans across multiple industries. Each sector applies the tool differently, but the fundamental principle of load distribution remains the same.

1. Construction Industry

In construction, spreader-bars are essential for lifting heavy beams, precast concrete sections, roofing structures, and steel frames. A spreader-bar ensures that loads are balanced, preventing tilting or damaging fragile construction elements.

2. Shipping and Logistics

Shipping yards often use telescopic spreader-bars to lift large containers. These bars adjust to the container’s size, ensuring safe handling during transport and reducing the risk of container damage.

3. Marine and Sailing

In sailing, spreader-bars are used in mast and rigging systems to maintain sail shape and improve wind performance. They also appear in lifting applications when hoisting boats.

4. Offshore Oil and Gas

Heavy subsea equipment, pipes, and modules are often moved using modular spreader-bars due to their immense lifting capacity.

5. Industrial Manufacturing

Factories use spreader-bars to handle large machinery, delicate components, or bundled goods that must remain stable during movement.

6. Entertainment and Staging

Spreader-bars are used in rigging for stage equipment, lighting, or props where balance and safety are critical.

Benefits of Using Spreader Bars

Spreader-bars provide multiple advantages over simple sling or hook lifting methods:

- Enhanced Safety: Reduces risks of tipping or slipping.

- Load Protection: Prevents bending, crushing, or damage to fragile loads.

- Stability: Ensures the load is evenly balanced and controlled.

- Flexibility: Adjustable and modular bars handle multiple load shapes.

- Efficiency: Saves time in lifting operations by improving control.

- Compliance: Meets safety regulations in construction and shipping.

Comparison: Spreader Bars vs. Lifting Beams

Often confused, spreader-bars and lifting beams serve similar purposes but differ in design and application.

| Feature | Spreader Bar | Lifting Beam |

|---|---|---|

| Structure | Rigid bar with slings attached at ends. | Beam that bears load directly. |

| Load Transfer | Forces are vertical, evenly distributed. | Beam carries bending stresses. |

| Weight | Generally lighter. | Heavier structure. |

| Application | Containers, fragile or large items. | Shorter spans, concentrated loads. |

| Cost | Usually more affordable. | Higher cost due to structure. |

Safety Considerations in Spreader Bar Use

Safety is critical in lifting operations. Using a spreader-bar incorrectly can lead to accidents or equipment failure. Key safety guidelines include:

- Load Capacity Awareness: Always use within rated capacity.

- Inspection: Check for cracks, corrosion, or wear before each lift.

- Rigging Practices: Ensure slings and chains are secured properly.

- Operator Training: Only trained personnel should operate lifting systems.

- Environment Assessment: Be cautious of wind, uneven surfaces, or obstructions.

Challenges and Limitations

Despite their many benefits, spreader bars are not without challenges:

- Transport and Storage: Large modular spreader-bars can be cumbersome.

- Setup Time: Assembling adjustable or modular bars requires extra time.

- Specialization: Some bars are only suitable for specific loads.

- Cost for Heavy-Duty Bars: High-capacity spreader-bars can be expensive.

The Future of Spreader Bar Design

With the increasing demand for efficiency, sustainability, and safety, the future of spreader-bars is evolving. Potential innovations include:

- Lightweight composites to reduce weight while maintaining strength.

- Smart sensors embedded to measure stress and load in real time.

- Automation integration with cranes and lifting machines.

- Eco-friendly coatings for marine and offshore applications.

Conclusion

The spreader bar may appear as a simple tool, but it plays a crucial role in modern industries by enhancing safety, protecting loads, and improving efficiency in lifting and rigging operations. Its versatility—from construction and shipping to manufacturing and entertainment—demonstrates why it remains one of the most reliable devices in heavy-lifting engineering.

By understanding the types, benefits, applications, and safety considerations of spreader-bars, businesses and operators can make informed choices that improve operational outcomes. As innovation continues, the spreader-bar will only become smarter, safer, and more efficient, reinforcing its indispensable role in global industries.

FAQs

1. What is a spreader bar used for?

A spreader bar distributes loads evenly during lifting, preventing damage or instability in construction, shipping, and industrial applications.

2. How is a spreader bar different from a lifting beam?

A spreader bar uses slings to spread loads vertically, while a lifting beam carries the load directly and is heavier.

3. Can spreader bars be adjusted for different loads?

Yes, adjustable and telescopic spreader bars can adapt to various load sizes, making them highly versatile.

4. What industries rely heavily on spreader bars?

Industries such as construction, logistics, shipping, offshore oil, manufacturing, and entertainment frequently use spreader bars.

5. Are spreader bars safe for heavy lifting?

Yes, spreader bars are safe if used within their rated capacity and with proper inspection and rigging practices.